A custom-made, stable, and elegant carport, installed in just a few days.

No more costly foundations and endless construction projects —

Welcome to the new generation of screw foundations and turnkey solutions.

Our foundation screws anchor precisely into the ground, thanks to real-time electronic control by our installation machines. Installation is quick, clean, and respectful of your land, without concrete or heavy excavation. A modern and eco-friendly solution, designed to last.

Decklab manages the entire project, from design to installation, with the support of a partner design office and specialized technicians. Present on site at every stage, we guarantee precise monitoring and controlled execution.

No more standard kits and the short-lived quality of mass-produced products. Each Decklab carport is custom-designed to blend seamlessly with your home's architecture and meet your specific needs.

At our company, custom design is not an option: it's in our DNA.

Our structures are designed to withstand the most demanding Swiss weather conditions, whether it be heavy snow at the end of the season, heavy rain, or increasingly intense hailstorms. This guarantees a reliable, stable, and durable shelter that retains its strength and elegance over the years.

A safe investment, for today and tomorrow.

From the initial idea to the final installation, we transform your project into a solid, elegant, and durable reality.

Each screw is installed using an electronically controlled screwdriving machine, which measures soil resistance and anchoring force (in kN) in real time.

This data allows each foundation to be checked and adjusted until the required stability is achieved according to the project load.

If resistance varies during screwing, we immediately adjust the installation to ensure optimal anchoring.

This technology provides an accurate reading of the terrain, which is invisible with a concrete foundation, and ensures that each anchor is perfectly adapted to the actual soil conditions.

A Decklab foundation can be installed in just a few hours, without digging, formwork, or waiting for it to dry.

The ground remains intact, the site clean, and the environmental impact minimal.

This method significantly reduces implementation costs by avoiding the need for heavy machinery and additional labor days.

What if your project evolves one day?

The screws can be removed, moved, or reused without leaving marks or damaging the ground.

Dig, formwork, pour, wait for it to dry...

Concrete remains a reliable method, but it involves long, messy, and costly construction projects, often disproportionate for lightweight structures such as carports.

It permanently alters the terrain and makes any subsequent modifications complex.

Screw foundations offer a modern alternative: stable, environmentally friendly, and ready in record time.

They protect the floor, improve installation accuracy, and offer the flexibility to adapt or modify the project over time, without constraints.

Thanks to this system, the first stage of the project is already a step in the right direction: fast, reversible, and respectful of the soil.

Less impact, more precision—a project that starts well and remains flexible over time.

Decklab innovation means precision of movement and control of the terrain – guaranteed stability over time.

Sleek design, flat roof with minimalist styling.

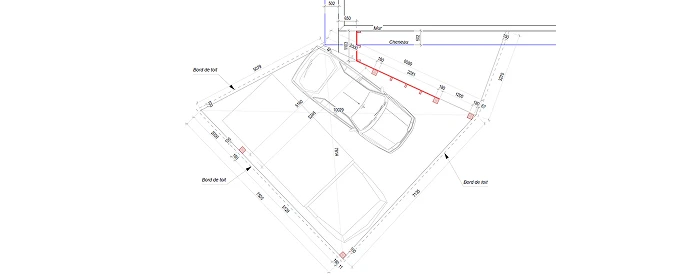

Long span without central post. Stability guaranteed by beam calculations and soil resistance recorded by our Bluetooth-connected screwdriver.

Site survey reveals soil too soft for one of the foundations; increase the size of the screw to achieve the required value.

Custom-built structure for two vehicles with optimized lateral overhang.

Overhang calculated for maximum protection when exiting the vehicle, stability ensured by reinforced foundations.

Simple, clean design. Flat roof. Harmonious integration of wood cladding.

Foundation anchored deeply to withstand frequent alpine winds. Ground load measured electronically to ensure the weight of wet snow for this high-altitude construction.

Elevated shelter, custom-made for a motorhome.

Screw foundation capable of ensuring the

additional weight generated by the overhang (2.05 m) of the eaves.

Curved roof for a unique architectural design. Integration of storage space.

lateral.

It all starts with listening carefully to your needs and conducting a detailed study of your environment. Together, we design a custom carport, designed to blend harmoniously with your home and meet your aesthetic and functional expectations. You receive a clear and comprehensive proposal, based on the expertise of a carpenter-designer.

Once the project has been approved, we prepare for implementation in the field. Our screw foundations are installed in just one day, without digging, without waiting and without blocking your access : you leave in the morning, and by evening your space is free again, ready to accommodate the structure. A fast, clean, and precise method that guarantees a perfectly stable base from day one.

In our workshop, each element is manufactured and prepared with precision, according to the measurements taken on your site. Some parts may be pre-assembled or adjusted in advance, when this improves efficiency on site. Thanks to this careful preparation and the fact that we laid the foundations ourselves, we know exactly how each element will fit into place.

The result: smooth, precise editing with no surprises.

The final assembly is carried out by us, continuing the work prepared in the workshop. No multiple contractors, no wasted time: a single trusted expert, from start to finish. You benefit from a reliable, elegant shelter that blends perfectly into your space.

Decklab: the simplicity of turnkey solutions, the precision of customization.

At Decklab, quality is not just about high-end materials; it is measured by the accuracy of every choice.

Our strength comes from our versatility: designing, adapting, and finding the most relevant solution, whether technical, aesthetic, or economic.

The privilege of having been able to observe and build in different countries has allowed us to adopt the most effective methods, those that combine common sense, efficiency, and sustainability.

It is this agile approach, rooted in Swiss rigor and enriched by a practical openness to the field, that allows us to offer controlled, sustainable, and competitive projects without ever compromising on precision or quality.

— Dario Krebs, founder and carpenter.

Yes, absolutely.

Each screw is installed using an electronically controlled screwdriving machine, which measures soil resistance and anchoring force (in kN) in real time.

This data can be used to verify that each foundation meets the required values (per foundation/post individually) according to the project load.

Thanks to this method, each anchor is perfectly adapted to the nature of the terrain—unlike a concrete foundation, which, even if massive, can sink or tip over if the ground is not perfectly stable.

The price does not depend solely on the dimensions or design:

The materials, finishing details, or choice of paint or UV protection also influence the final budget.

As a rough guide, a single carport generally costs between CHF 10,000 and CHF 15,000, while a double carport can easily cost between CHF 17,000 and CHF 25,000, depending on the customer's preferences and assembly methods.

We are happy to offer a free, personalized assessment to evaluate your project with complete transparency.

If a detailed technical study (plans, calculations, choice of specific materials) is desired, its cost—generally between $250 and $500—will be deducted in full from the final price if an order is placed.

In general, the complete installation of a Decklab carport takes between two and five days, depending on the size of the project.

Screw foundations can be installed in a single day, without digging or blocking your access.

You leave for work in the morning—in the evening, your space is free again, ready for the next stage of assembly.

Depending on the municipality and the size of the project, a permit may be required.

Decklab guides you through these steps and provides the technical plans required for the application.

The owner then submits the application, with our advice and ready-to-use documents.

Let's talk about it: every project is unique, and we take the time to respond to it with precision.